Reduced Shank Screws for Railway Transportation

In the railway transportation sector, safety and reliability are essential, especially when dealing with mechanical components subjected to cyclic stresses and extreme environmental conditions. In this context, reduced shank screws represent an advanced technical solution, designed to ensure maximum fatigue resistance and long-term durability.

EFS supports its customers in selecting and supplying these solutions, offering screws manufactured according to specific project requirements and carefully selecting the most suitable materials and finishes.

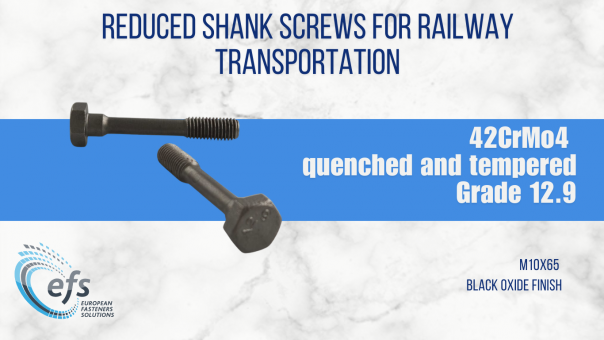

Case Study: Reduced Shank Screws Supplied by EFS for Railway Applications

A significant example of EFS's technical support is the recent supply of screws for a major customer in the railway sector. These are hex head screws, manufactured based on the client’s technical drawings, ideal for critical applications where fatigue resistance and fastening stability are paramount.

Technical features of this supply include:

Type: Hex head screw.

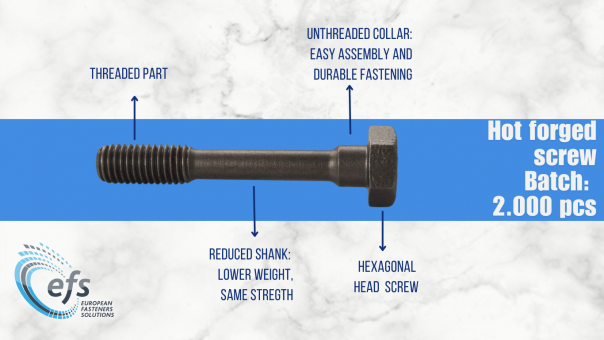

Manufacturing: Hot-forged, with production batches of 2,000 pieces.

Dimensions: M10x65, featuring a reduced shank to minimize weight without compromising strength.

Material: 42CrMo4 quenched and tempered steel, grade 12.9, with black oxide finish.

Certification: Inspected and certified by DNV Inspectors (3.2 Certification).

The use of 42CrMo4 steel is a strategic choice for applications under high loads. This quenched and tempered steel offers excellent hardenability, mechanical strength, and good machinability.

The 12.9 grade, indicating a tensile strength of approximately 1200 N/mm², is one of the highest available for fastening elements, making it ideal for critical connections in railway vehicles.

For further details, you can consult the EFS resistance class table.

What Makes a Reduced Shank Screw Special

What makes these screws particularly suitable for the railway sector?

The main feature is the reduced shank diameter compared to the threaded section. This design allows the screw to stretch elastically under load, improving stress distribution and reducing the risk of fatigue failure.

The presence of an unthreaded collar between the head and the reduced shank also facilitates assembly and disassembly operations, avoiding the risk of seizure within the hole. This results in a more robust and durable fastening system, capable of effectively meeting the maintenance and safety requirements of the railway sector.

Typical Applications in the Railway Sector

Reduced shank screws are widely used in situations where components are subjected to cyclic vibrations and dynamic loads. In the railway industry, these screws are typically used for:

Fastening wheel hubs and brake discs, where fatigue resistance is crucial.

Elastic joints and connections exposed to continuous vibrations.

Transmission systems and other mechanical components that require highly reliable fastenings.

In these scenarios, the use of standard screws would offer lower performance in terms of safety and durability. This is where the added value of reduced shank screws supplied by EFS becomes evident.

Surface Treatments for Maximum Durability

To withstand the most aggressive environmental conditions, such as exposure to humidity, salt spray, or chemical agents, specific surface treatments can be applied.

At the customer’s request, this screw underwent a black oxide treatment. This chemical treatment gives the steel a dark finish while providing protection against oxidation and enhancing the component’s aesthetic appearance.

In other cases, the screws may undergo a surface treatment known as Geomet®, a high-performance anti-corrosion coating with a thickness between 5 and 10 µm. This treatment, based on passivated aluminum and zinc flakes, is particularly effective against salt spray corrosion, making it ideal for outdoor or humid environments. Visually, it is easily recognizable by its characteristic silver color.

Reference Standards: A Guarantee of Safety

Safety is a fundamental principle in the railway transportation world. For this reason, the use of reduced shank screws must comply with strict technical standards and regulations.

The main applicable standards are:

EN 15085: European standard defining the quality requirements for welding railway vehicles and their components.

UIC 864-3: International regulation specifically for fasteners used in railway applications.

EN ISO 898-1: Concerning the mechanical properties of carbon and alloy steel fasteners.

The use of these screws must always be planned during the design phase, with precise calculations that consider the stresses the components will be subjected to.

Conclusions

The reduced shank screws for railway transportation supplied by EFS represent the perfect combination of technology, safety, and mechanical strength. Thanks to its in-depth knowledge of industry regulations and its ability to provide customized solutions, EFS positions itself as a strategic partner for companies operating in the railway sector.

Choosing EFS means relying on an experienced partner capable of supporting customers at every stage: from selecting the most suitable materials to choosing the right surface finishes, all the way to the punctual supply of batches that meet the most stringent technical specifications.