Certificazioni

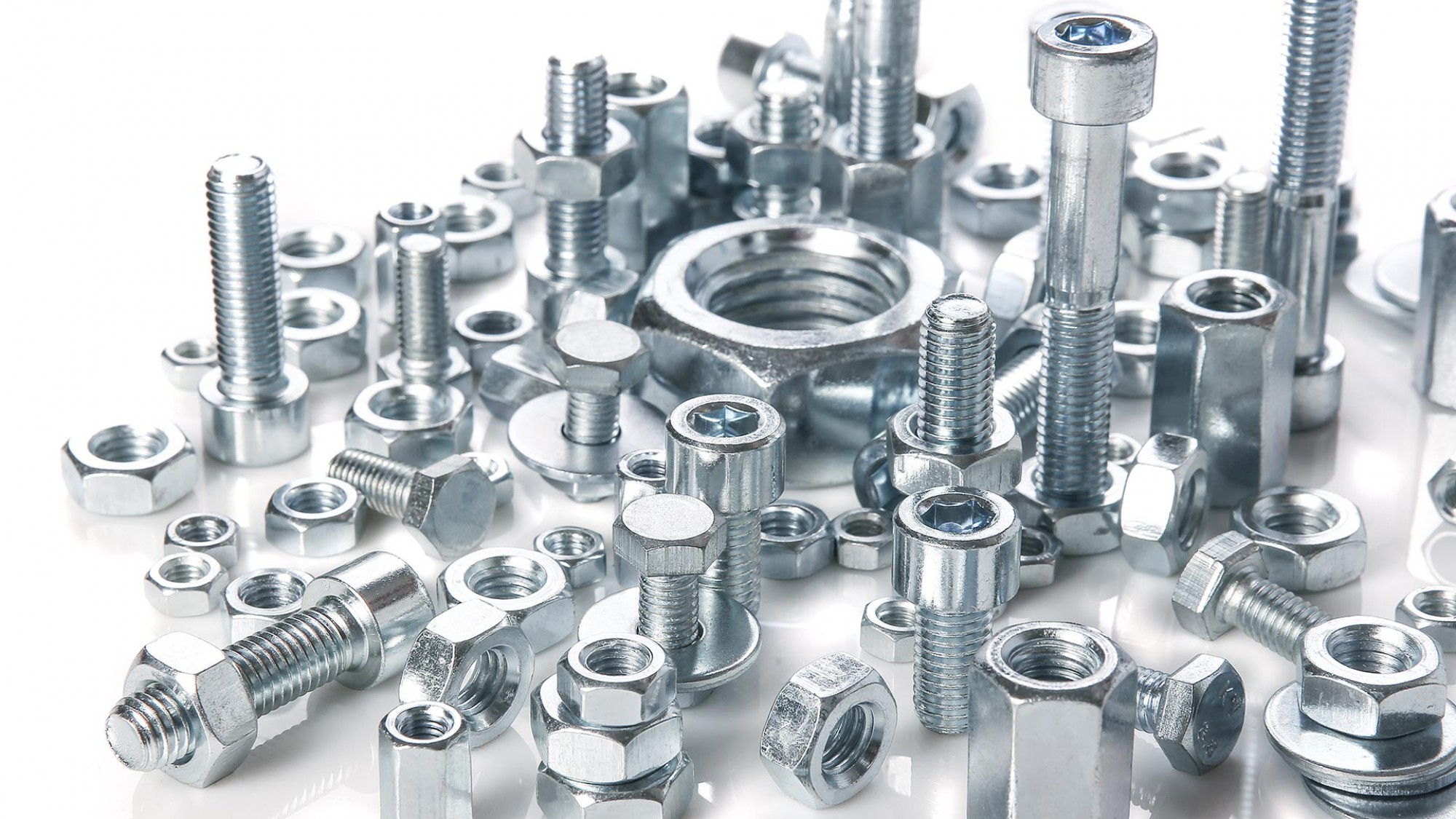

Fasteners are mechanical devices whose fundamental function is to combine several components of the product or structural systems. Metal fasteners such as rivets, screws, pins, nuts and bolts are used to join the distinct parts to obtain the final product.

Depending on the design requirements, it is possible to classify the fasteners in: